The Crucial Role of Magnetic Powder Brakes in Tension Control Applications

Tension control is essential for a wide range of industrial processes, specifically when flexible materials like films, paper textiles, metals and wires are unwound, processed, or rewound. The ability to maintain a consistent tension during the process is crucial for maintaining product quality, avoiding damage to the material, and improving the efficiency of operations. Magnetic powder brakes have been identified as among the top efficient solutions for tension control because of their precise torque control, longevity, and flexibility.

Table of Contents

How Magnetic Powder Brakes Work in Tension Control

Magnetic powder brakes make use of chambers that are that is filled with magnetic powder which is magnetized after the electromagnetic field is stimulated. By altering the intensity in the field, the braking torque can be precisely adjusted. This produces an even as well as adjustable resistance to rotating that is then applied to the shafts or rollers that handle the material. This ability to finely control torque allows the operator to maintain the tension they want in the material that is being processing.

Advantages of Magnetic Powder Brakes for Tension Control

1. Precise and Smooth Torque Control

Magnetic powder brakes are an extremely precise and smooth control of the braking torque. By changing the magnetic field strength they offer a consistent resistivity that is adjusted to keep the exact tension needed. This is crucial for materials that are delicate and processes that require high speed where tension fluctuations could cause problems or damage to the material.

2. Non-Contact Operation and Reduced Wear

In contrast to mechanical brakes which rely on friction surfaces magnetic powder brakes function without contact with moving parts while the braking. This type of operation is a significant reduction in the wear and tear of the brake, while also extending the life of the brake as well as reducing maintenance requirements.

3. Quick and Reliable Response

The control by electromagnetics of magnetic powder brakes permits rapid adjustments of the brake force. This rapid response permits the control of tension in processes that have varying speeds or abrupt changes, assisting to ensure stability and preventing material breaking.

4. Enhanced Heat Dissipation

Modern designs for magnetic powder brakes have better cooling mechanisms and resistant to heat. These features help to disperse the heat produced during the continuous braking process, which prevents overheating and ensuring stability during long operating times.

5. Compact and Lightweight Design

Modern magnetic powder brakes are designed to be small and lightweight, but without impacting the power capacity. This makes them easy to incorporate into machines with limited space and improves overall efficiency.

6. Energy Efficiency

The magnetic powder brakes use energy only to create the magnetic field required for the braking torque. The latest designs are optimized for the efficiency of the magnetic circuit and coil and reduce energy consumption when in comparison to other braking techniques which is advantageous in power-sensitive applications.

Tension Control Applications of Magnetic Powder Brakes

This chart outlines why magnetic powder brakes help improve tension control systems resulting in better product quality across a variety of industries.

| Application Industry | Description | Impact on Tension Control Process and Product Quality |

| Printing Industry | Maintains consistent web tension during high-speed printing. | This ensures a precise registration of the print ensures accuracy, minimizes errors, and helps reduce the amount of waste. |

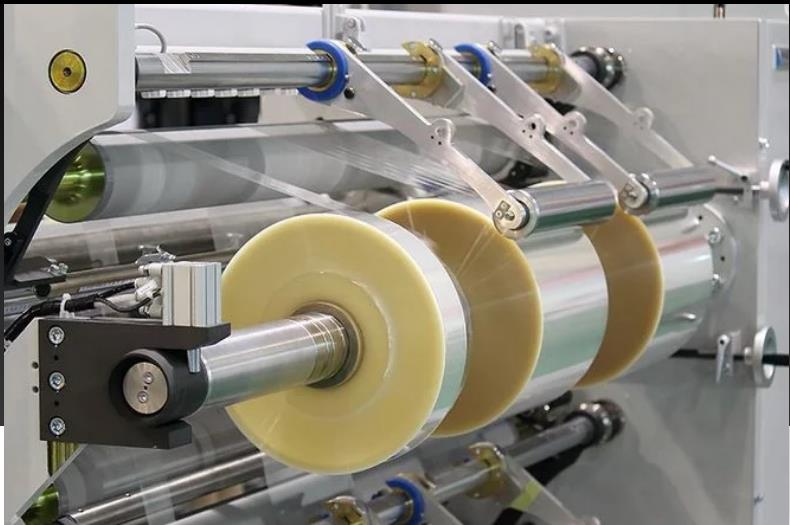

| Flexible Packaging | Controls the tension in laminates and films during production. | It prevents wrinkles, tears and deformation of the material and improves the integrity of packages. |

| Textile Manufacturing | Controls the tension of fabric and yarn during weaving and processing. | The fabric is not stretched or distorted to maintain the quality of the fabric and its consistency. |

| Metal Foil and Wire Processing | Smooth unwinding and rewinding wires and foils. | Reduces surface imperfections and breakage Enhances product durability and finishing. |

| Paper Converting | It provides a stable tension for cutting, slitting and winding. | Creates uniform edges and clean rolls, enhancing the final appearance. |

| Laminating and Coating | Maintains a uniform tension for uniform application of adhesives and coatings. | It ensures consistency of coating and strength of bonding, which reduces Rework. |

| Plastic Film Processing | Tension controls to stop distortion during winding and extrusion. | Maintains the stability of dimensionality and quality of the surface of films. |

Recent Advancements in Magnetic Powder Brake for Tension Control Application

As demands for manufacturing evolve towards faster speeds, higher accuracy, and better operations, recent advancements in the field of magnetic powder brakes have dramatically improved their performance, reliability, and integration capabilities.

1. Improved Electromagnetic Coil Designs

One of the major advances is the advancement of electromagnetic coils that create greater and more uniform magnetic fields. These advancements allow for more precise control of tension braking, allowing for more uniform tension regulation across a variety of operating conditions. This includes the fluctuating load and variable speeds.

2. Enhanced Magnetic Powder Materials

Recent advances in the magnetic powder composition have produced powders with better magnetic properties and greater the tolerance to heat. These advances increase the torque output and speed of response while keeping the degradation to a minimum due to the heat and long-term use which extends the lifespan of brakes.

3. Integrated Cooling Technologies

To reduce the risk of heat build-up in continuous operation, innovative methods of cooling, like integrated air cooling and liquid cooling channels — have been developed. These cooling systems effectively disperse heat while maintaining the brake’s performance while prevent damage to the brake and the material.

4. Compact, Lightweight Designs

With the use of new methods of manufacturing and materials Magnetic powder brakes are now smaller and lighter without sacrificing torque capacity. This allows for a simpler installation on machines with limited space while also enhancing or maintaining efficiency.

5. Smart Digital Controls and IoT Connectivity

Digital control systems that are equipped with sensors are now able to provide real-time monitoring of important parameters such as temperature, torque and wear. When combined with IoT platforms that are connected, it allows for remote diagnostics, predictive maintenance and automatic tension adjustments, thus increasing the efficiency of operation and decreasing the amount of downtime.

6. Energy Efficiency Enhancements

Modern advances in coil winding methods and the optimization of magnetic circuits reduce the power usage for magnetic brakes. These advances help reduce operating costs and are in line with the increasing focus of industry on eco-friendly, energy-efficient manufacturing processes.

7. Greater Customization and Application Versatility

The latest magnetic brakes are designed more precisely to fulfill the particular tension control requirements of various applications ranging from fast printing, to fine textile processes as well as heavy-duty handling of metal foil. This flexibility leads to improved quality of the product and increased reliability.

Final Thoughts

The magnetic powder brakes have proven their place as essential elements in tension control in various industries. Their precise, smooth and reliable torque control of magnetic powder brakes enhances the quality of products while minimizing material loss and wear on equipment. With constant innovations, magnetic powder brakes are continuing to improve, bringing higher performance, efficiency and flexibility to meet the needs of the modern manufacturing environment.