Why Web Tension Controllers are Important in Flexible Packaging Processes

The world of flexible packaging is dynamic and intricate, requiring precision, consistency, and efficiency. Web tension controllers stand out as critical players among the different components and technologies that assure seamless operations. These controllers are critical in maintaining ideal tension levels in flexible packaging processes, which contributes to higher quality, reduced waste, and overall efficiency. In this article, we examine the crucial role of web tension controllers in flexible packaging processes, including their functionality, benefits, and industry-changing influence.

Learn the Basics of Web Tension Controllers

| Aspect | Description |

| Definition | Devices used to monitor and adjust tension levels in moving webs to maintain consistency and quality. |

| Importance | Essential for preventing material defects and ensuring smooth operation in web handling processes. |

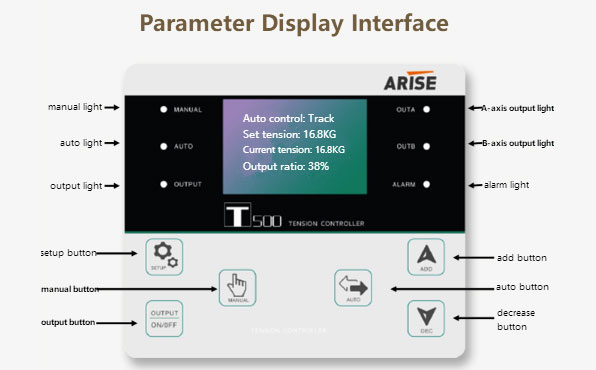

| Components | Tension sensors, controller unit, actuators, interface. |

| Types | Open-loop and closed-loop tension controllers. |

| Benefits | Improved quality, increased productivity, cost savings, ease of operation. |

| Functionality | Measure tension, calculate adjustments, communicate with actuators, provide user interface. |

| Operation | Can operate based on preset parameters or with feedback from tension sensors. |

| Use Cases | Printing, converting, packaging, textile, and other web handling industries. |

| Considerations | Material properties, process speed, roller diameters, system dynamics. |

| Future Developments | Integration with Industry 4.0 technologies for enhanced automation and data analytics. |

The Functionality of Web Tension Controllers in Flexible Packaging Processes

Flexible packaging involves the manipulation of materials that are intrinsically sensitive to variations in tension, such as films, foils, and laminates. The consistent application of tension is essential to maintain the integrity of these materials as they traverse printing, laminating, slitting, and winding processes. A minor imbalance in tension can lead to a domino effect of issues, including misalignment, wrinkles, and even material breakage. This not only compromises the packaging’s aesthetic and functional aspects but also hampers efficiency and increases waste.

The web tension controller is at the heart of optimum tension control. This device acts as a diligent conductor, arranging the packing material’s dance throughout its voyage. To adjust tension, they use advanced tension control algorithms and real-time data from strategically positioned sensors. These controllers make instantaneous adjustments to maintain the proper tension levels by continuously monitoring factors like as material tension, speed, and diameter.

Key Benefits of Web Tension Controllers in Flexible Packaging Processes

1. Consistent Product Quality

Web tension controllers ensure consistent tension levels across the web of flexible packaging materials, resulting in uniform product quality. Consistency in tension prevents issues such as wrinkles, creases, or misalignment during the printing, laminating, or converting processes, leading to higher-quality finished products.

2. Reduced Material Waste

By maintaining optimal tension levels, web tension controllers minimize material waste associated with defects or errors in the packaging process. Proper tension control prevents material overstretching, tearing, or wrinkling, reducing scrap rates and maximizing material utilization, which is especially crucial for expensive or delicate packaging materials.

3. Improved Machine Efficiency

Web tension controllers optimize the performance of packaging machinery by ensuring smooth and uninterrupted web handling. By eliminating variations in tension that can cause machine stoppages or jams, tension controllers enhance machine efficiency and throughput, reducing downtime and maximizing production capacity.

4. Enhanced Print Registration

In printing applications, accurate web tension control is essential for achieving precise print registration and color alignment. Web tension controllers maintain consistent tension levels during the printing process, ensuring sharp, accurate prints with minimal registration errors or misalignments, resulting in higher-quality packaging graphics.

5. Greater Process Flexibility

Web tension controllers offer the flexibility to adjust tension settings based on specific packaging materials, printing speeds, or process requirements. This adaptability allows manufacturers to accommodate a wide range of substrates, printing inks, or production conditions, optimizing performance across different applications and production environments.

6. Reduced Operator Intervention

Automated web tension control systems reduce the need for manual adjustment and monitoring of tension levels during production. By continuously monitoring and adjusting tension settings, tension controllers minimize operator intervention, freeing up personnel to focus on other critical tasks and improving overall process efficiency.

7. Prevention of Machine Damage

Inadequate tension control can cause excessive stress on machinery components, leading to premature wear and tear or equipment damage. Web tension controllers prevent overloading or underloading of machine parts by maintaining optimal tension levels, prolonging the lifespan of packaging machinery and reducing maintenance costs.

8. Compliance with Quality Standards

Web tension controllers help manufacturers meet stringent quality standards and customer specifications for flexible packaging products. Consistent tension control ensures that packaging materials meet dimensional tolerances, thickness specifications, and performance requirements, enhancing customer satisfaction and brand reputation.

Conclusion

Web tension controllers emerge as unsung heroes in the fast-paced and intricate world of flexible packaging, ensuring the smooth flow of activities. The automatic tension controllers are functioning in maintaining ideal tension levels translates to better product quality, less waste, and greater operational efficiency. Web tension controllers will stay at the forefront of innovation as the flexible packaging industry evolves, pushing advancement and contributing to the production of top-tier packaging materials that protect and enhance the items they encapsulate.