100% Full-color Print Inspection for High-value Products

In today’s highly competitive market, the authenticity and printing quality of high-value products are under constant scrutiny. Industries like pharmaceuticals, packaging, security printing, etc, heavily rely on precision print inspection to convey brand trust and maintain customer confidence. Any deviation in printing quality, such as color mismatch, misregistration, or printing defects, can lead to brand damage or regulatory issues. This is why 100% full-color print inspection systems are critical.

Table of Contents

Why Print Inspection is Important for High-value Products

Ensuring Brand Integrity

The high-value products, such as cosmetics, luxury goods pharmaceuticals, luxury packaged foods, are dependent on a flawless packaging design to communicate the highest quality and ensure trust among consumers. Print inspection makes sure that each product is in line with brands’ visual and aesthetic requirements, which includes accurate colors, sharp logos and sharp images. Any deviation could diminish the perception of value, damage customer trust, and harm the reputation of the brand. By ensuring consistent quality of print manufacturers strengthen their commitment to quality and ensure the integrity of their brands.

Maintaining Regulatory Compliance

Industries like food, pharmaceuticals and beverages are subject to stringent regulations that require exact identification of ingredients, dosage guidelines as well as safety warnings along with expiration date dates. Print inspections help ensure that each product is in compliance with these standards, avoiding costly errors, recalls or even legal sanctions. Achieving accurate print verification is crucial in ensuring the safety of consumers and complying with industry standards.

Enhancing Consumer Confidence

The worth of an item on the packaging. The clear accurate, precise and visually consistent printing ensures that the product is of the standards of excellence. However, text that is not aligned properly or smudges or inconsistent colors can raise questions regarding authenticity and quality even if the item itself is perfect. An effective print inspection strengthens confidence and increases the likelihood of to purchase more often.

Preventing Counterfeiting and Fraud

The most expensive products are frequently victims of counterfeiters. Advanced printing inspection can detect and avoid forgery by checking the intricate details of printing such as holograms, variable codes as well as various other features for security. In ensuring that the authenticity of packaging and precise manufacturers can ensure their earnings and retain customer trust.

Reducing Waste and Production Costs

Print inspection allows for earlier detection of problems by reducing waste materials and reducing the need to reprint. Through detecting errors in real time, companies can improve their production processes, increase efficiency and reduce expenses associated with damaged products. This is especially crucial when it comes to high-value products where the cost of manufacturing costs and materials are high.

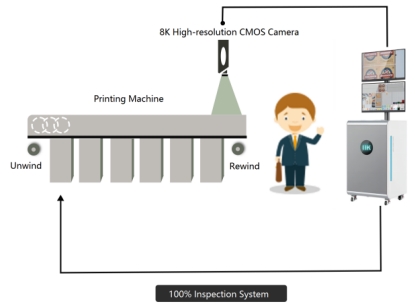

What is 100% Full-color Print Inspection

As opposed to random sample inspection, 100% inspection implies that each printed item is examined in real time throughout production. When it is combined with full-color imaging it analyzes the accuracy of color and uniformity at the pixel level. The systems take high-resolution pictures that show the image. They then compare them to reference standards and identify any deviations immediately.

Key Technologies Behind the 100% Full-color Print Inspection Systems

100% full-color printing inspection system combine advanced imaging technology, intelligent software, and automation to guarantee flawless output.

1. High-resolution Color Imaging

The core of 100% full-color print Inspection systems lies high resolution color imaging. The systems utilize sophisticated cameras that can capture small detail across all printed objects. In contrast to traditional inspection methods which rely on eye-to-eye checks and random samples, higher resolution imagery makes sure that every item is scrutinized for consistency of color and text clarity as well as graphic precision. Full-color imaging permits the system to spot subtle differences in saturation, hue and brightness. These are essential for products with high value such as pharmaceuticals, luxury products and packaging that is premium.

2. Advanced Image Processing Algorithms

The images that are captured are processed by sophisticated algorithms that detect flaws with great accuracy. These algorithms can analyze real-time photos with template templates, identify misalignments streaks, smudges or missing components and analyze variable data like serial numbers, QR codes or barcodes. Modern systems typically use AI and machine-learning to identify acceptable variations and real imperfections, thus decreasing false positives and increasing the precision of inspection.

3. Real-time Defect Detection and Feedback

Real-time processing is an essential technology that helps print inspection systems identify and correct defects in a timely manner. If a flaw is found the system could activate alarms or remove items that are defective out of the process. This immediate feedback can keep defective products from making it to the market, assuring consistent quality and minimising the amount of waste.

4. Smart Integration Manufacturing Systems

Web inspection systems for printing quality can typically integrate seamlessly to production equipment and software for quality monitoring. This allows inspection data to be shared in real time which allows automated maintenance and process optimization and central quality control. When connected to the Industry 4.0 platforms, manufacturers get an extensive view of their production efficiency and are able to make informed decisions that improve efficiency and decrease cost.

5. Adaptive Lighting and Optics

The ability to capture accurately the details of prints is dependent on the optical technology and lighting. The adaptive lighting systems adjust the intensity as well as angle and spectrum to reveal imperfections and guarantee high-quality color even for reflective or rough surfaces. High-precision optics are focused on capturing every tiny aspect, making sure that any imperfections that may be missed by the human eye are detected with confidence.

6. High-speed Data Processing

To keep up with the speed of production lines, Modern printing inspection systems use advanced data processing technology that can be processed at high speed. Highly efficient processes and optimized software structures allow systems to handle huge amounts of high-resolution image information in real-time without slowing production. This means that speed doesn’t affect precision, even in high-throughput applications.

Applications across Industries of 100% Full-color Print Inspection

This chart shows how 100% full-color inspection ensures accuracy, compliance and brand protection across diverse industries.

| Industry | Application | Purpose |

| Pharmaceuticals | Labels for packaging, dosage directions Safety warnings Serialized codes | Assure compliance with regulations, the safety of patients, as well as the prevention of counterfeiting |

| Luxury Goods & Cosmetics | Logos, packaging for products embossed, metallic or embossed | Maintain the image of your brand, maintain uniformity of color, and superior perception of the product |

| Food & Beverages | Ingredient labels, nutritional facts, expiration dates, promotional designs | Avoid misbranding, ensure the confidence of the consumer, and be in compliance with the regulations. |

| Security Printing | Certificates, banknotes, ID cards, secure documents | Secure against counterfeits, increase authenticity, and guarantee traceability |

| Consumer Electronics | User manuals, product labels and warranty seals | Make sure you have accurate information and maintain ensure brand coherence |

| Industrial Packaging | Labels for machinery, chemicals and other specialized items | To ensure compliance, readability with the law, in addition to safe handling dangerous materials |

Future Trends in 100% Full-color Print Inspection for High-value Products

Several key trends are influencing the future of print inspection technology, which promise greater precision, efficiency, and flexibility.

1. Integration of Artificial Intelligence and Machine Learning

One of the most important changes in inspection of prints is the incorporation using artificial intelligence (AI) and machine-learning (ML) techniques. These tools allow systems to “learn” from production data which improves their ability to discern between legitimate variations and imperfections. As time passes AI-powered inspection systems are able to adjust to the changing conditions of printing as well as detect previously undetected defects, and minimize false positives. This allows the manufacturers of high-value products to keep their accuracy high while reducing waste.

2. Increased Speed and High-throughput Capabilities

As production lines get faster inspection systems are changing to keep up with the pace, but without compromising the accuracy. The future of print inspection technology will make use of rapid imaging and real-time processing with high-speed data handling to check every item, even on the most efficient production lines. This will ensure that quality assurance will be able to scale as manufacturing demands increase especially in industries where large-scale production and accuracy are equally crucial.

3. Enhanced Color Accuracy and Precision

Future systems will feature sophisticated image sensors and adaptive lighting and optical technologies that will ensure an even higher degree of color accuracy. The latest developments in spectral analysis and multi-angle imaging will permit inspection of surfaces with complex structures reflective materials, reflective surfaces, and metallic inks. These are used in luxury products cosmetics, premium packaging. These enhancements will ensure uniform branding and exact colour reproduction for every product made.

5. Integration with Smart Manufacturing and Industry 4.0

Full-color printing inspection is now an integral part of the smart manufacturing ecosystems. The future is pointing towards more Integration to Industry 4.0 platforms, where inspection data is fed into central Quality management software. This integration allows for the use of predictive maintenance and process improvement and monitoring in real-time across many production lines. Manufacturers can gain valuable information to minimize errors, increase efficiency, and make informed decisions across the entire process of production.

6. Adoption of Cloud-based Analytics and Remote Monitoring

Cloud technology will enable inspection systems to store and analyze huge quantities of production data remotely. Manufacturers will have the ability to examine print quality in real-time across a variety of factories, evaluate trends in defect and make corrective steps while not on site. This feature helps to streamline global operations, improves quality control, and enables the collaboration of quality managers, engineers and other brand stakeholders.

7. Focus on Sustainability and Waste Reduction

As environmental issues grow and print inspection technology evolves, the future will be focused on the reduction of energy and waste. Early detection of defects can prevent loss of materials, and AI-driven process optimization will reduce the requirement for repeated printing. Through combining precise printing inspection with sustainable practices, manufacturers can cut expenses while still achieving the corporate social responsibility and environmental objectives.

Final Thoughts

For high-value products, 100% full-color print inspection is a necessity. Through ensuring zero-defect printing, safeguarding brand integrity, complying with strict regulations, reducing waste and production costs, etc, these printing inspection systems enable manufacturers to deliver high-quality products without printing defects.