How Much Do You Know About Web Tension Controller

A web tension controller is a device used to maintain the tension of a material or web during the manufacturing or production process. The device monitors the tension using sensor feedback and makes adjustments to the process to maintain a consistent tension level.

Common Types of Web Tension Controllers

Pneumatic Web Tension Controller

Air pressure is used by these controllers to adjust the tension of the web. They are typically used in applications requiring high precision, such as the production of thin films or foils.

Magnetic Particle Tension Controller

It uses magnetic particles to create a magnetic field on the web, which adjusts the tension. They are typically used in applications where high accuracy and speed are required.

Electronic Tension Controller

It measures the tension of the web with electronic sensors and makes adjustments to maintain a consistent tension level. They are typically used in applications that require a high level of precision and flexibility.

Common Disadvantages Of Web Tension Controller On The Market

1. Complexity

It is possible that they are complex devices that require specialized knowledge to operate and maintain. Setting up and calibrating a controller can be time-consuming, and trained technicians may be required to ensure accurate and dependable performance. Because of this complexity, troubleshooting and repairing problems can be difficult, resulting in downtime and production delays.

2. Compatibility

Not all web tension controllers work with all web handling equipment or materials. Before purchasing a controller, make sure it is appropriate for your application. Some controllers, for example, may not be compatible with high-speed operations, whereas others may not be suitable for use with specific types of web materials.

3. Sensor Placement

Sensors are used to measure the tension of the web. The placement of these sensors, as well as any vibrations or other environmental factors that may interfere with their performance, can affect their accuracy. Finding the best sensor placement can be difficult, and it may take some trial and error to achieve the desired results.

4. Maintenance

It must be serviced on a regular basis to ensure accurate and dependable performance. Calibration, sensor cleaning, and the replacement of worn or damaged components are all examples of maintenance. Failure to perform regular maintenance can reduce the controller’s accuracy, reliability, and lifespan.

5. Electrical Requirements

It must be powered by electricity to function. This power source must be compatible with the voltage and current requirements of the controller. Furthermore, the controller may produce electromagnetic interference (EMI), which may interfere with other electronic devices in the manufacturing process.

6. Learning Curve

Learning how to use an automatic web tension controller can be a difficult task, especially for those who are unfamiliar with the technology. Operators must be trained on how to set up and calibrate the controller, as well as troubleshoot and adjust problems. This may take some time and may necessitate the use of additional resources to ensure that operators are properly trained.

Advantages Of Double Loop Web Tension Controller

Two Feedback Loops

To achieve precise tension control, the double-loop tension controller employs two feedback loops. The first loop uses a tension sensor to measure web tension and compare it to a setpoint value. The second loop modifies the control output based on the difference in tension between the actual and setpoint values. When compared to single-loop controllers, this two-loop approach produces a more accurate and stable control signal.

Advanced Signal Processing

It filters out noise and other unwanted signals that could interfere with the tension measurement using advanced signal processing techniques. This can include the use of low-pass filters, signal averaging, and other techniques to ensure the accuracy and reliability of the tension signal.

PID Control Algorithm

The control output is adjusted using a PID control algorithm based on the difference between the actual tension and the setpoint value. To achieve precise and stable tension control, this algorithm computes the proportional, integral, and derivative terms of the control signal. The PID algorithm can be fine-tuned for optimal control performance in a variety of web handling applications.

Multiple Input and Output Options

It supports a wide range of web handling applications by providing multiple input and output options. Inputs for tension sensors, speed sensors, and other feedback devices, as well as outputs for actuator control, alarms, and other control signals, can be included.

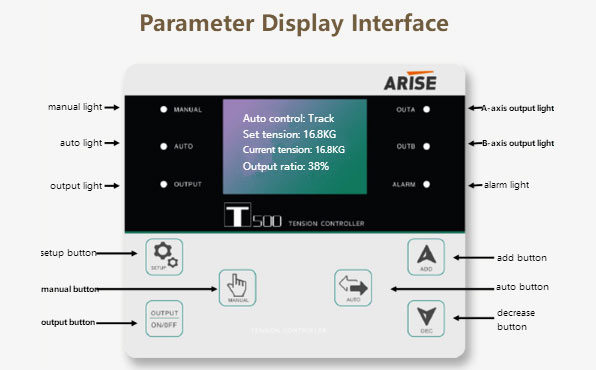

User-Friendly Interface

A user-friendly interface on a double-loop tension controller allows operators to monitor and adjust tension control parameters in real time. This can include a graphical representation of the tension signal, setpoint values, and control output, as well as user-friendly menus and controls for modifying the PID algorithm, filter settings, and other parameters.

Easy Integration with Existing Systems

It is intended to integrate easily with existing web handling systems, such as motors, drives, and other control devices. They are adaptable to a wide range of communication protocols, including analog, digital, and fieldbus interfaces.

High-Reliability and Durability

Web tension controller is designed to operate in harsh industrial environments and provide reliable and durable performance. They are typically built with high-quality components, including rugged housings, industrial-grade electronics, and robust connectors and wiring. This ensures that the controller can withstand the rigors of continuous operation and provide long-lasting performance.

Summary

Web tension controller is essential in a variety of coil industries including industries of paper, film, foil, textiles, and nonwovens. These materials typically require precise web tension control to ensure that they are produced to the correct specifications and quality standards.