Non-contact Web Guide Sensor Technologies

Accurate web guiding is critical in the printing, packaging, textiles, and film processing industries to ensure alignment, minimize waste, and maintain consistent quality. In the past, moving webs and shifting lateral position were tracked using contact and mechanical sensors. However, emerging technologies have led to the development of automated, non-contact web guide sensors, which have proven more accurate, reliable and flexible in difficult industrial settings compared to the traditional contact sensors.

Table of Contents

Understanding Non-contact Web Guide Sensors

Non-contact web guide sensors identify position on the web without physically interacting with the material. This eliminates the chance of mechanical interference and also the contamination and countermands perilous substrates. Detection technologies like ultrasonic, infrared, optical, or even capacitive, real time assess edges of the web, centerlines, or other parameters on the surface of the web.

Why Non-contact Web Guide Sensors are Essential

Maintaining Product Quality

The automatic alignment of the sensors during the production phase in non-contact web guide systems is critical. Poor alignment can cause defects in coating, and gaps in the printing, which can be detrimental to the overall quality of the output during production. Non-contact systems have the ability to track alignment within their set parameters and adjust themselves to maintain quality output during production.

Reducing Material Waste

Web material waste is a principal cost consideration in web-based production activities. With non-contact sensors, non-scrap correcting the position of a web in mid-flight avoids the presence of non-touch errors, which could necessitate the rejection of product trims or cause unacceptable expenditure of excess material. This not only avoids wastage but makes the overall productive process far more sustainable.

Protecting Delicate Materials

Modern webs, which include thin sheets of polymer film slits, very thin metallic foils, and ultra-fine specialty textiles, have a very low threshold of sensitive physical contact. Sensors which perform non-contact alignment avoid the risk of irreparable scratching, tearing, or unacceptable configurations in the distortion of the materials in question, while blasting precise alignment.

Enhancing Operational Efficiency

Hold and web alignment corrections while automating non-contact performing sensors improve overall production. Less touch intervention is required. Both automated and manual processes are balanced, allowing NP. Operators on the burns are freed up and can pay attention to more important things, balancing more complex tasks.

Integration with Automation Systems

Non-contact web guiding sensors are compatible with other non-contact systems: digital oversight, machine’s eye, including remote moderators, and other control meshes. The linkage fosters non-contact aim to improve processes and automate pivoting maintenance and QA while resourceful non-touch systems are brought.

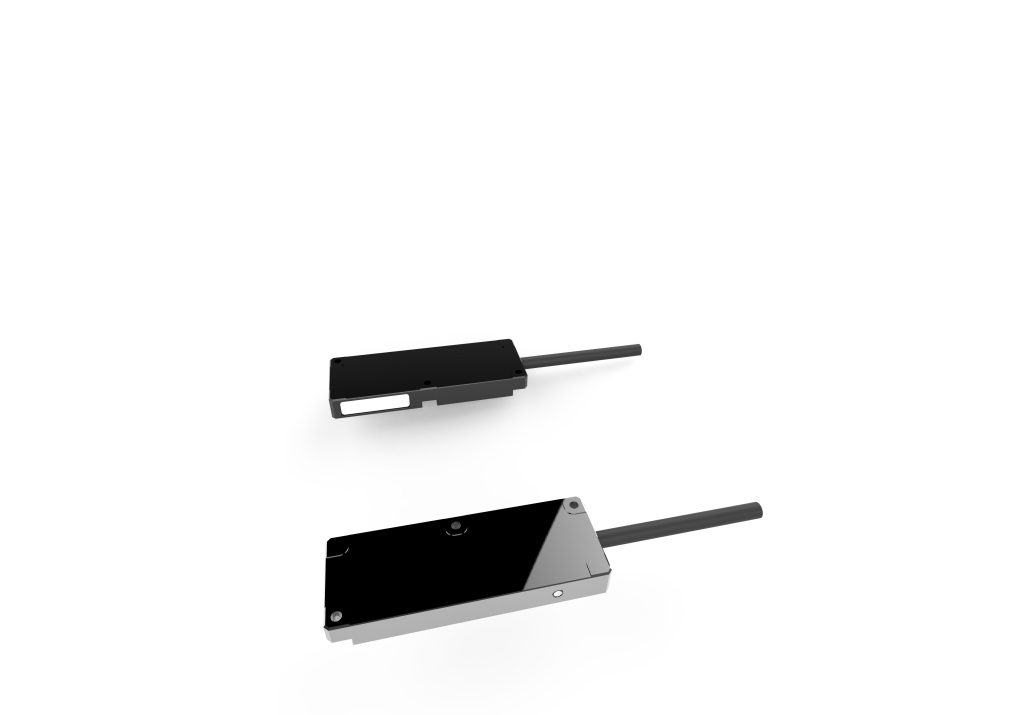

Types of Non-contact Web Guide Sensor Technologies

This chart summarizes the main non-contact web guide sensor technologies and their practical use in industry.

| Type of Sensor | Working Principle | Key Advantages | Typical Applications |

| Ultrasonic Edge Sensor | Measures distance to the web edge using reflected sound waves. | Works with opaque, transparent, or reflective materials; unaffected by color, gloss, or print patterns; durable in harsh environments. | Packaging films, labels, opaque or reflective materials. |

| Optical Sensor | Uses visible light to detect the web edge, centerline, or printed marks. | Highly accurate; suitable for thin or transparent webs; capable of detecting fine details; fast response. | High-speed printing, film processing, textile alignment. |

| Infrared Edge Sensor | Uses infrared light to detect the web edge or printed marks. | Can detect transparent or reflective materials; less affected by ambient lighting; non-damaging to delicate materials. | Transparent films, foils, coatings, or substrates sensitive to visible light. |

| Capacitive Sensor | Detects changes in electrical capacitance caused by the presence or absence of the web material. | Effective for non-conductive materials; works with very thin webs; stable under variable conditions. | Paper, plastics, textiles. |

| Vision / Camera-based Sensor | Uses cameras and image processing to monitor web position, alignment, and print registration. | Extremely precise; enables defect detection and quality control; adaptable to complex patterns; supports data collection for automation. | Printing registration, quality assurance, advanced film and textile processes. |

How Non-contact Sensors Work in a Web Guide System

This chart provides the step-by-step process of how non-contact sensors detect, process and correct web alignment in a web guide system.

| Step | Description | Technology Examples | Outcome |

| 1. Detection | The sensor detects the lateral position of the moving web without touching it. | Ultrasonic waves, optical/infrared beams, capacitive sensing, vision-based cameras | Accurate measurement of web edge or centerline |

| 2. Data Transmission | Positional information is sent to the web guide controller. | Electrical signals, digital communication | Real-time data transfer to the control system |

| 3. Signal Processing | Controller analyzes the data to determine if corrective action is needed. | Microprocessor, control algorithms, PLC integration | Determines magnitude and direction of adjustment |

| 4. Actuation | Corrective commands are sent to actuators or servo-driven rollers. | Servo motors, pneumatic or electric actuators | Web position is adjusted laterally to maintain alignment |

| 5. Continuous Feedback | System continuously monitors web position and repeats the correction cycle. | Closed-loop control system | Maintains precise alignment in real time, even at high speeds |

| 6. Integration & Optimization | Sensor data can be integrated with automation systems for monitoring and process optimization. | IIoT platforms, machine vision, AI-based systems | Enhanced efficiency, reduced waste, predictive maintenance |

Future Outlook of Non-contact Web Guide Sensor Technologies

The continual advancements of these sensors within the activities of automation systems, digital systems and the development of smart blended activities within the production environment are bound to be of critical importance in terms of balancing efficiency with quality in the multiple production sectors.

Integration with Smart Manufacturing

As sensors become more able to ‘speak’ to Smart Manufacturing systems, the advances of these systems in the future hinge on non-contact web guide sensors. Sensors connected to the Industrial Internet of Things (IIoT) platform allow real-time web alignment monitoring, analysis, and performance optimization. This interconnectedness streamlines maintenance, lowers unscheduled production halt occurrences, and enhances the longevity of sensors and production instruments.

Advancements in Vision and AI Technologies

The future web guiding technologies are particularly poised to benefit from the application of Vision and AI with non-contact web guide sensors. These systems enhance the already existing web guiding technology, enabling higher precision and adaptive control. In addition to web position alignment, these systems are programmable to pattern analysis, defect detection, and auto adjustment to material inconsistencies. Machine learning, coupled with high-resolution imaging control, the possibilities of real-time decision making, waste control, and product quality improvement escalation.

Increased Accuracy and Speed

As production moves closer to its upper constraints, non-contact sensors will have to develop ways to remain accurate at much higher speeds of web movement. Advancing sensors will more than likely have asynchronous signal processing and feedback loops, along with advanced capability processing and high resolution detection, adjusted to hold accurate control at varying tension, temperature and material conditions.

Expanded Applications Across Industries

The multaporpose non-contact web guide sensors will allow for use in sectors beyond the current printing, packaging, textiles and film processing industries. Industries such as electronics, medical films and advanced composites which deal with high value sensitive materials will also start to leverage the capability of these sensors for their precision alignment and quality assurance.

Emphasis on Sustainability

Advances in the non-contact web guide sensor technology will also promote manufacturing self sustaining technologies. For instance, the sensors reduce energy waste and minimal alignment of materials, conserves production processes materials with precision control. Thus, the sensors will advocate for more green production procedures.

Summary

The advancement of non-contact web guide sensor technologies contributes immensely to the systems of modern manufacturing. Highly accurate and versatile while maintaining a high standard of cohesion throughout the manufacturing process, these web guiding control systems, including non-contact sensors, reduce excessive costs and resource utilization and help overcome structural maintenance obstacles. These non-contact sensor technologies, which maximize system optimization and performance, are in high demand due to the never-ending pursuit of smarter, more automatic production systems.