Product Articles

Why Does My Web Guiding System Fail at High Tension Levels?

Increasing web tension appears to be an easy answer in many production lines. In theory, higher tension can help improve flatness, eliminate wrinkles, and even stabilize the process. However, engineers…

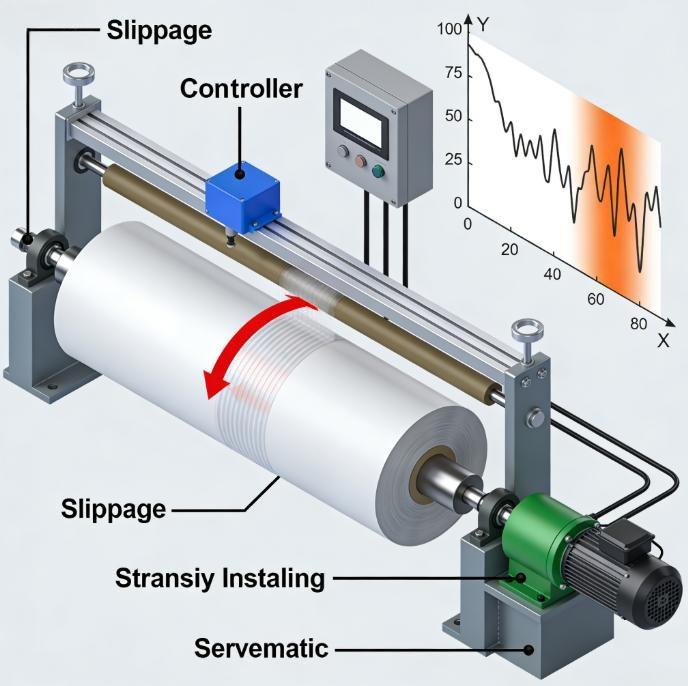

How to Prevent Web Slippage in Tension Control Systems?

Web slippage is frequently the main reason for the lack of stability in roll-to-roll tension control systems, resulting in unstable tension, poor register accuracy, and high material waste. It usually…

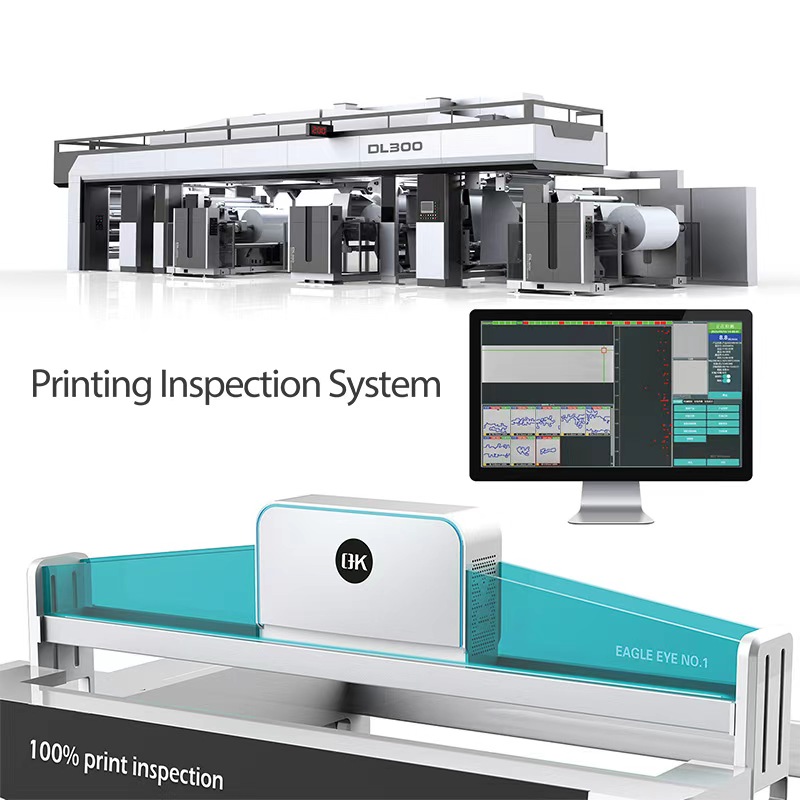

100% Inspection System: Actual Installation Steps and Precautions

In the production of printing, a missing character, a tiny color shift, or a registration error may happen from time to time and go undetected by either manual checks or…

How to Reduce Printing Defects in High-Speed Web Production?

In the printing and converting industries that rely heavily on the web, increased production speed is mostly considered a shortcut to the desired outcome of higher output and lower unit cost…

Traditional Sampling Inspection vs. 100% Print Inspection: What’s the Real Gap?

While traditional sampling inspections are slow and ineffective at keeping pace with modern-day production scanning, printing quality standards are rapidly increasing. Common problems being faced are missed defects, material loss,…

How Web Inspection Systems Work for Ensuring Label Quality

In the packaging and labeling industry, it is very important to maintain a certain quality standard. Quality standards are important because labels are more than just identifying a brand, they…

The Use of 100% Print Inspection in High-speed Printing Industries

Maintaining consistent quality across high-speed printing industries is a significant challenge. The growth in speed and volume of printing makes traditional print quality control methods, like manual inspection, become impractical. This is where…

Laser-based vs. Camera-based Web Guide Systems: Which Technology to Choose

Web guide systems align the web consistently, preventing misalignment, which can cause defects, waste and downtime. Laser-based and cameras-based systems are two of the most commonly used technologies for web guiding. Each system has…

Automatic Adjustment and Feedback in Print Inspection

Printing industries today still have the challenge of ensuring the uniformity of the output quality while keeping the volume of high output. Defects can occur due to uneven ink distribution, problems…

Camera vs. Sensor Technologies in 100% Print Inspection Systems

Implementing 100% print inspection systems is a great way to maintain quality in printing operations, as these systems automatically monitor and review the output of print jobs in real-time. Such systems…